We are proud to announce that we have won the Red Dot Design Award 2020 for our new compact Centerless Grinding CUBE 350! The Red Dot Award is an international design competition for product design, communication design and design concepts.

The evaluation process is based on various judging criteria which are constantly adapted to new technical, social, economic and ecological requirements. They provide an orientation framework, which is complemented by each individual juror according to his or her expertise and socio-cultural background.

The judging criteria include amongst others:

- Degree of innovation

- Functionality

- Formal quality

- Ergonomics

- Durability

- Symbolic and emotional content

- Product periphery

- Self-explanatory quality

- Ecological compatibility

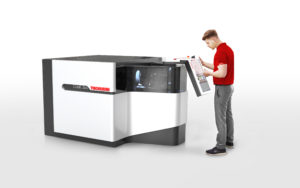

TSCHUDIN partnered with the Industrial Machines Design Expert Enrique Luis Sardi to develop another brilliant product together. The CUBE 350 impressed the jury with a self-contained, unusually elegant appearance. Thanks to an innovative layout, the machine is both ergonomic and efficient at the same time.

Minimal installation area

What sets the CUBE 350 apart in particular is its very small installation area (2558 x 1735 x 1320 mm). Users only need access to the rear of the machine to perform maintenance and servicing tasks, which means that several machines can be positioned together without any gaps. The philosophy when developing the CUBE 350 was to have “minimal area and maximum efficiency”.

Unique design

The grinder can be manually loaded in a safe and ergonomic way both by right-handed and left-handed users – a feature for which a patent application has been filed. The machine has a unique design with digitalised set-up and grinding processes to ensure the highest possible process stability and machine availability. Linear drives on the X, U and W axes ensure flexibility and productivity. The CUBE 350 was specifically developed for machining small components with part diameters of up to 20 mm.

Low-maintenance machine design

The CUBE 350’s simple and low-maintenance machine design helps to reduce operating costs. The natural granite machine frame and carriages guarantee thermostable, high-precision and a safe grinding processes. One major benefit of the machine is that it allows for easy and CE-compliant loading and unloading outside the grinding zone. TSCHUDIN’s “easy” software, which the company developed in-house, makes the device easy to operate and automate.

A wide range of process options

The patented, movable workpiece support ensures that the following range of process options is available: Roughing and finishing in a dual cycle, grinding sharp edges and controlled dressing of taper and radius. Its areas of application include plunge-cut grinding, grinding several operations in a single cycle, oscillation of the component during grinding and throughfeed grinding. This versatility means that the CUBE 350 is suitable for a wide range of applications – from toolmaking for very small batch sizes to medical technology and mass production in the automotive industry. Various materials can be processed – from steel to aluminium, glass, titanium, carbon, ceramics, germanium and silicon, amongst many others.