A fine serie

"The investment in a TSCHUDIN ecoLine 400 centerless grinding machine enables superfinishing of various precision parts in series production.”

Pascal Schiefer, Leibold Group

SYSTEM OVERVIEW

| Description | 400 ecoLine/proLine |

|---|---|

| Number of CNC axes | ecoLine 3 / proLine 4 |

| Through feed grinding range Ø | 100 mm |

| Plunge grinding range Ø | 150 mm |

| Grinding wheel width /Grinding lenght plunge grinding | max. 280 mm |

| Grinding wheels Ø | 400 mm |

| Grinding wheels bore diameter | 203.2 mm |

| Regulating wheels Ø | 250 mm |

| Regulating wheels bore diameter | 127 mm |

| Drive power grinding spindle | 15 / 29 / 37 kW |

| Peripheral speed grinding wheel (V-constant) | max. 63 m/s |

| Speed regulating wheel (infinitely variable) | 5-1000/min |

| CNC control | Fanuc 0i |

| Resolution | 0.1 µ |

| Dimensions L x T x H | 2860 x 2660 x 2080 |

| Weight | 10 t |

ecoLine & proLine

The unique TSCHUDIN centerless grinding machine concept with digitalised configuration and grinding processes is designed for the highest possible process stability and machine availability. Linear drives on the X-, U- and W-axis ensure flexibility and productivity. The centreless grinding machine proLine also has a patented fourth CNC-axis (Y-axis, Patent US 9.085.059) for vertical movement of the regulation wheel. The work rest and dressing tool of the regulation wheel are fixed in position at the height of the grinding wheel.

3 axes

Manual settings

U grinding wheel axis

W workpiece / dressing axis

X regulation wheel axis

Manual settings

1 – Configuring the workpiece superelevation

2 – Setting the height of the dressing tool

4 axes

Full automation

U grinding wheel axis

W workpiece / dressing axis

X regulation wheel axis

Y height adjustable regulation wheel

CNC controlled setting

of the regulation wheel height

The workrest and dressing tool of the regulation wheel are fixed in position at the height of the grinding wheel. This means the height of the workrest no longer needs to be adjusted.

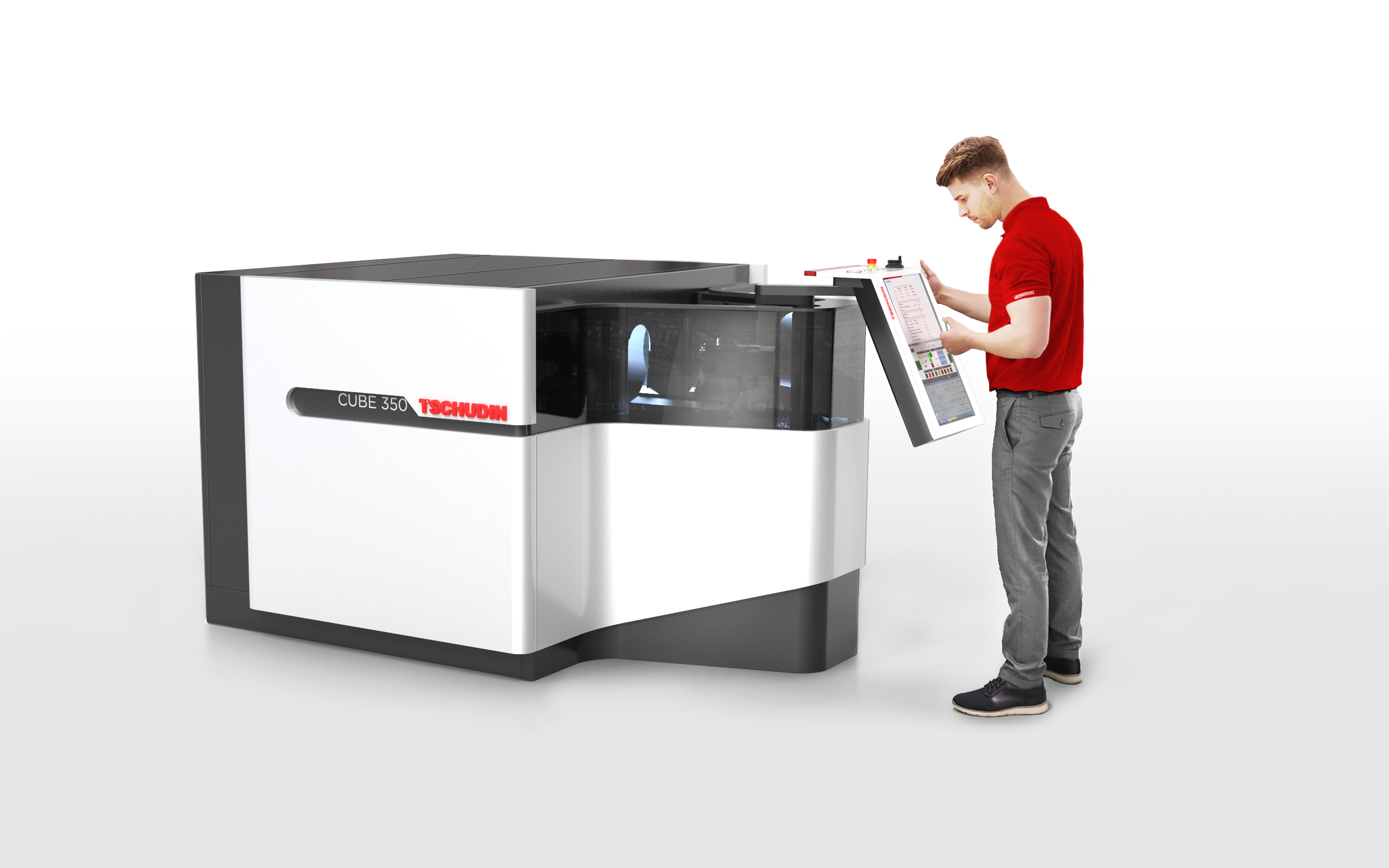

New compact centerless grinding machine

Cube 350 serie

- Minimum space, maximum efficiency

- All-rounder with short set-up times

- The compact centerless grinding machine enables safe and ergonomic manual loading by right-handed or

left-handed operators alike, patent pending. - The CUBE 350 has been developed specially for machining small components and small batch.

New centerless grinding machine

ecoLine / proLine Serie

- The centerless grinding machine 600 is special for machining large workpieces with diameters up to 250 mm and a length of up to 500 mm.